Features

FeaturesEffective Inventory Management

Inventory management is indeed a critical aspect of business profitability. Here are some tips to strike a balance between overstocking and understocking:

What are the 7 benefits from SQL Multiple branches control?

- Product Popularity Analysis

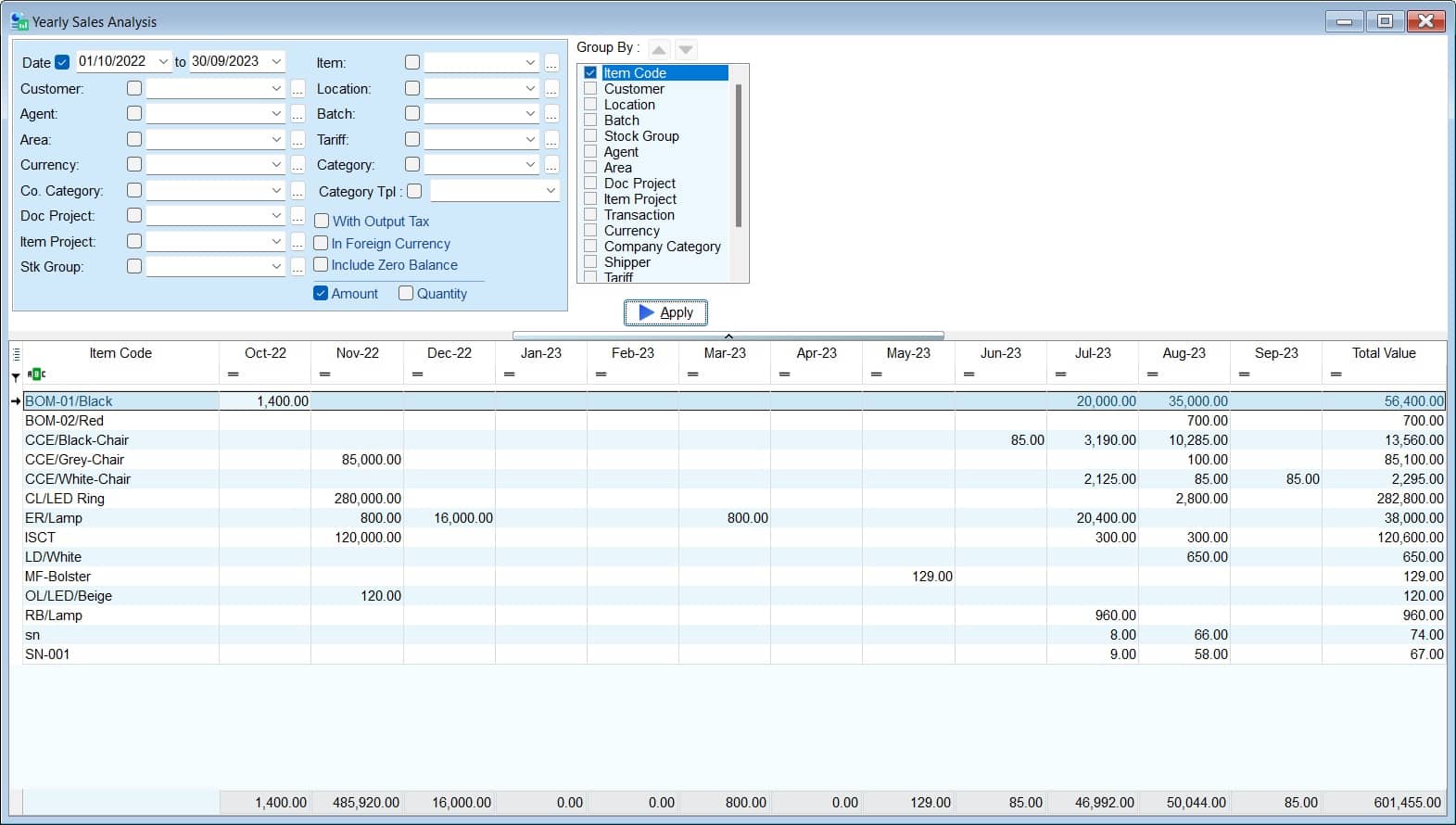

By using SQL Yearly sales analysis, you can easily identify :

- Best-selling products: Identify the most popular and in-demand products grouping by products and calculating the total quantity sold and revenue generated for each product. This gives you insights into which products are most popular among your customers over a 12-month period, helping you identify which products are in high demand during different months. This will give you a list of the best-selling products, which you can use to inform your inventory management and marketing strategies.

- Top revenue customers: You can use SQL to group by customers and calculate the total revenue generated by each customer over a 12-month period. This will give you a list of your top revenue customers, which you can target with special offers and promotions.

- Top-performing agents: You can use SQL to group by agents and calculate the total quantity sold or total amount sold by each agent over a 12-month period. This will give you a list of your top-performing agents, whom you can reward and incentivize.

Overall, SQL Yearly Sales Analysis is a valuable tool that can help businesses of all sizes improve their sales performance.

- Elevating Inventory Management with SQL: Forecasting, Seasonal Trends, and Optimization

Once you’ve identified your best-selling products and analyzed sales trends, SQL can improve your inventory management by:

- Ensuring that you have enough stock of high-demand items during peak seasons.

- Trimming down of slow-moving products to avoid overstocking and loss.

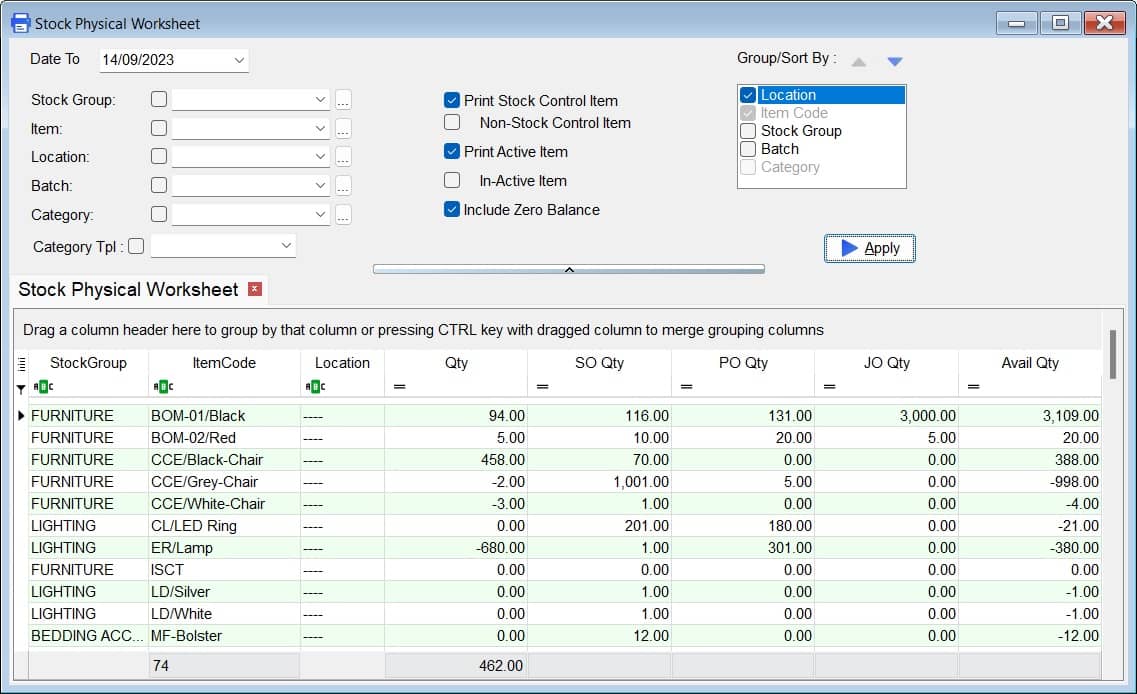

- Planning ahead by calculating your available inventory based on:

– Current quantity on hand

– Customer pre-orders (Sales Orders)

– Future order stock from suppliers (Purchase Order)

This will help you avoid stockouts and overstocking, and ensure that you have the right products in the right quantities to meet your customers’ needs.

By using SQL, businesses can forecast future inventory needs, identify seasonal trends in demand, optimize product placement in stores, and reduce shrinkage and theft. This can lead to increased sales, profits, and overall operational efficiency.

- SQL Stock Card Management: Precision, Control, and Efficiency

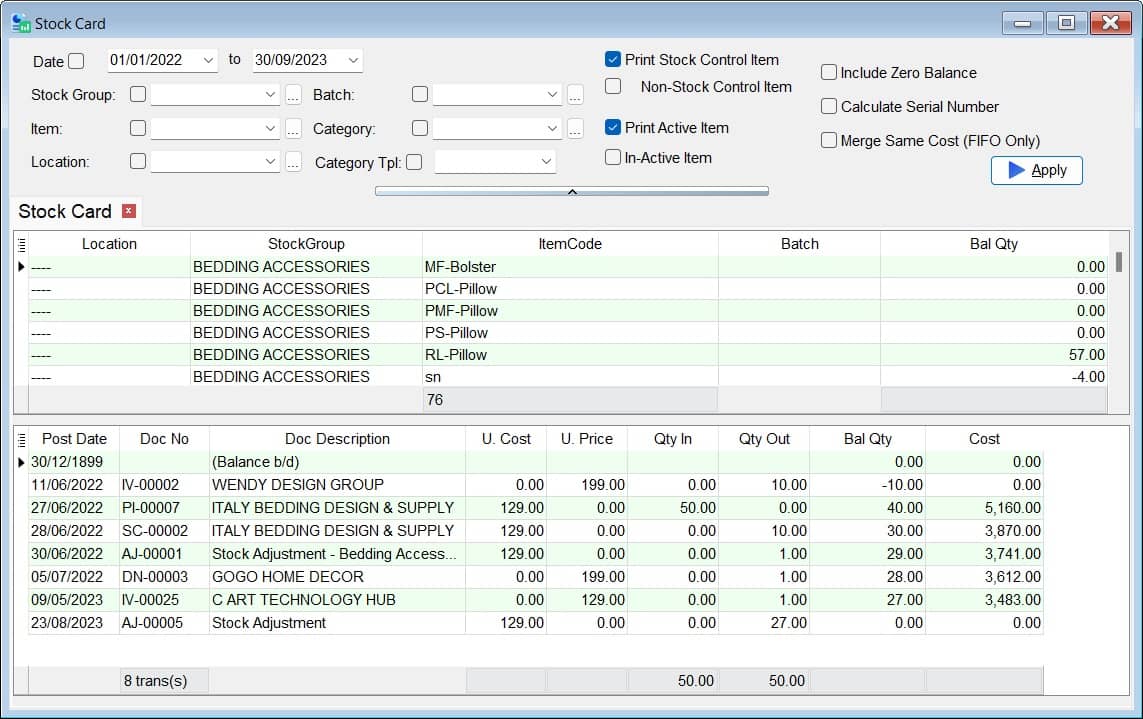

SQL Stock Card is a powerful tool that helps businesses track and manage their inventory in real time. It provides a comprehensive view of all stock movements, including purchase (stock in), sales (stock out), Internal Adjustment and current balances. SQL Stock Card can also track stock by location or batch, making it easy to identify products that are running low, oversupplied, or in specific locations.

Here are some specific examples of how SQL Stock Card can be used:

- A retail store can use SQL Stock Card to track the movement of products between its warehouse and retail stores, and to identify products that are running low and need to be reordered.

- A manufacturing company can use SQL Stock Card to track the movement of raw materials, work-in-progress, and finished goods, and to identify any potential bottlenecks in the production process.

- A wholesale distributor can use SQL Stock Card to track the movement of goods between its suppliers and customers, and to identify products that are in high demand or that are oversupplied.

No matter what industry you are in, SQL Stock Card can help you to improve your inventory management and profitability.

- How SQL Can Help You Avoid Double Orders, Track Outstanding Order, and Improve Customer Satisfaction

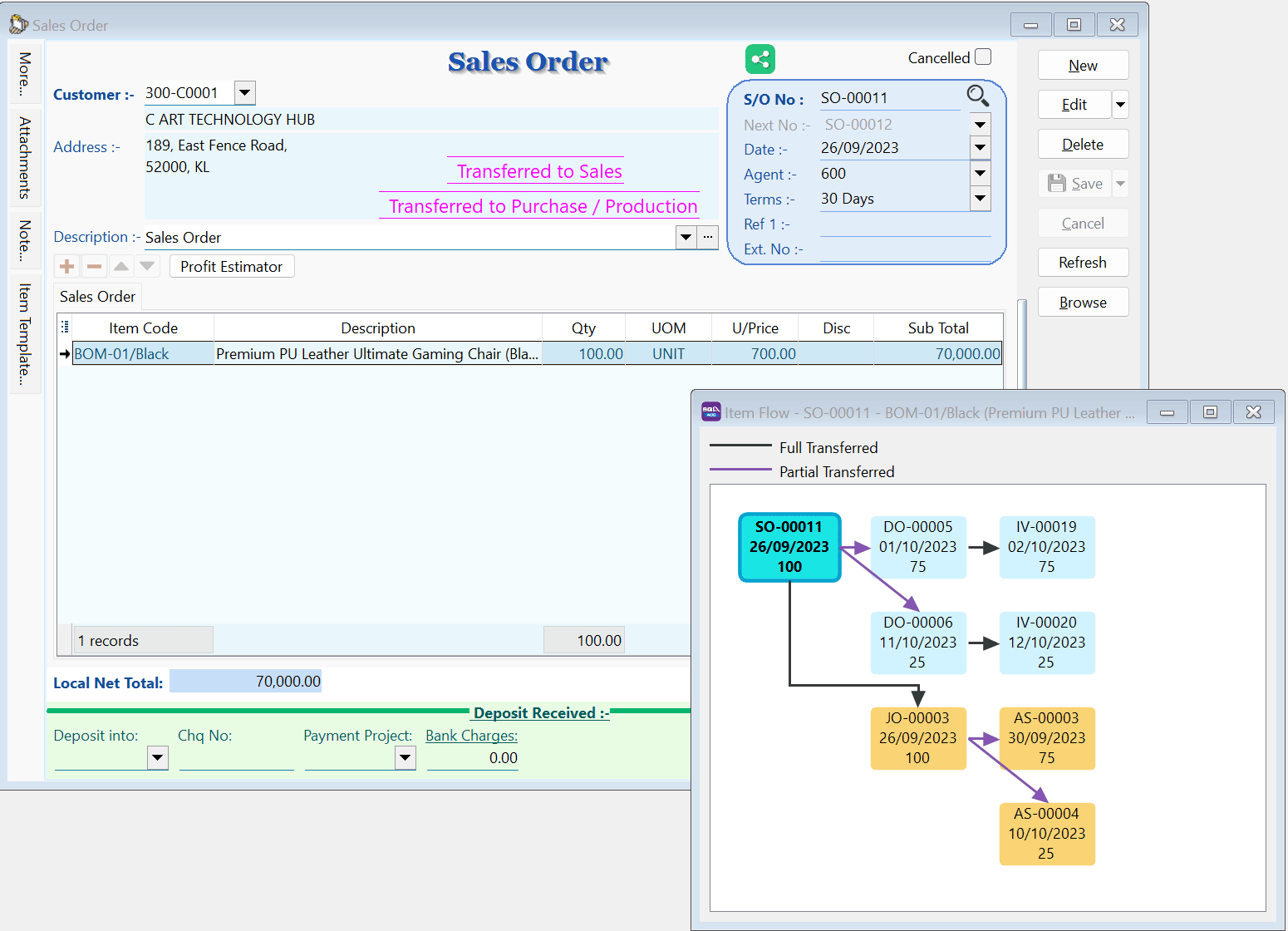

SQL can help you track the status of your purchase orders and sales orders in real time. With a single click, you can see the entire item flow, including the purchase order date, quantity ordered, and quantity outstanding by supplier. This can help you avoid double orders and follow up on outstanding stock from suppliers. Similarly, you can use SQL to track how many confirmed sales orders have yet to be delivered or invoiced.

Here are some specific examples of how SQL can be used to track the status of purchase orders and sales orders:

- A manufacturing company can track the progress of sales orders for finished goods based on customer specifications. It can track whether a sales order has been transferred to a job order to start manufacturing, and then whether it has been fully transferred to the assembly stage. This includes tracking the quantity, date, and any outstanding requirements for each sales order. Once production is complete, users can seamlessly transfer the sales order to initiate a delivery order. The entire item flow can be conveniently tracked and managed within SQL’s item flow system, streamlining the entire sales order fulfillment process.

- A retail store can use SQL to track the status of sales orders to ensure that customers receive their orders on time and in full.

- A wholesale distributor can use SQL to track the status of purchase orders from suppliers and sales orders to customers. This information can be used to identify and resolve any potential bottlenecks in the supply chain.

By tracking the status of your purchase orders and sales orders in real time, you can identify and address any potential problems early on. This can lead to increased customer satisfaction and profitability.

- SQL's Costing Methods, FIFO, and Real-Time Profit Margin Insights

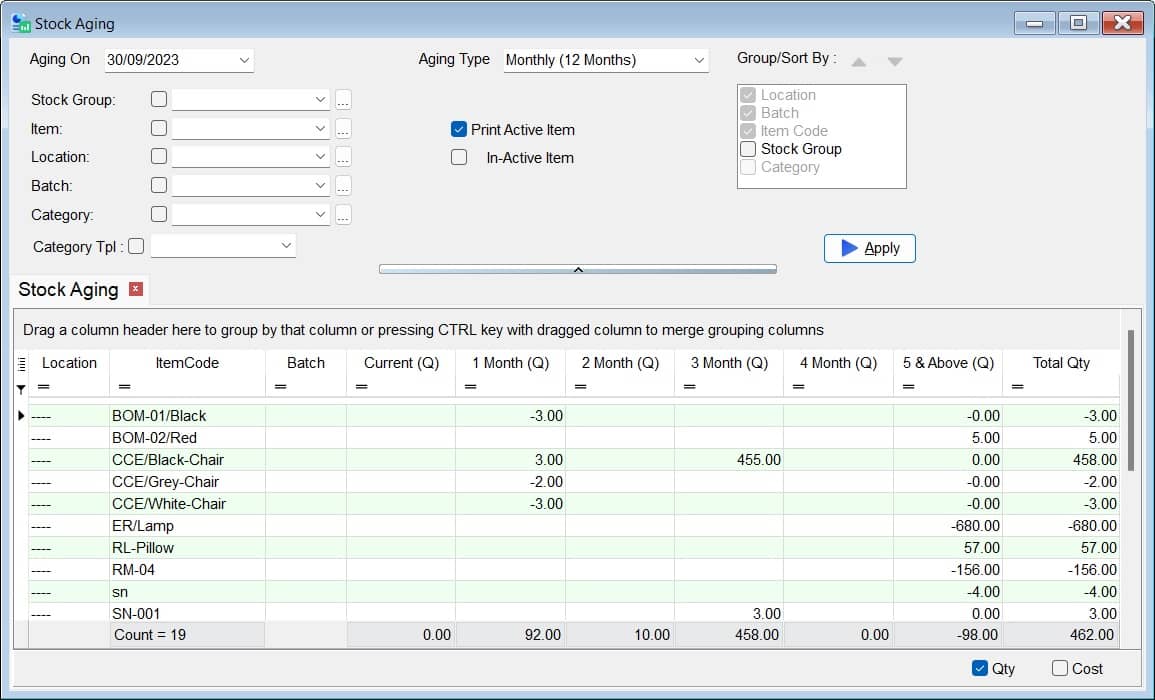

SQL is a versatile tool for costing and inventory management. It allows you to choose the best costing method for your industry and needs, and even set different costing methods for different stock groups. SQL also provides reports on stock aging, so you can identify old inventory and develop marketing strategies or promotions to clear it out.

Once you have set up your costing method, SQL Stock Card will automatically calculate accurate costing for you. This means that you can easily view itemized profit and margin based on real-time stock costing from sales profit and loss by document report, to track each individual sale, product, profit, and margin.

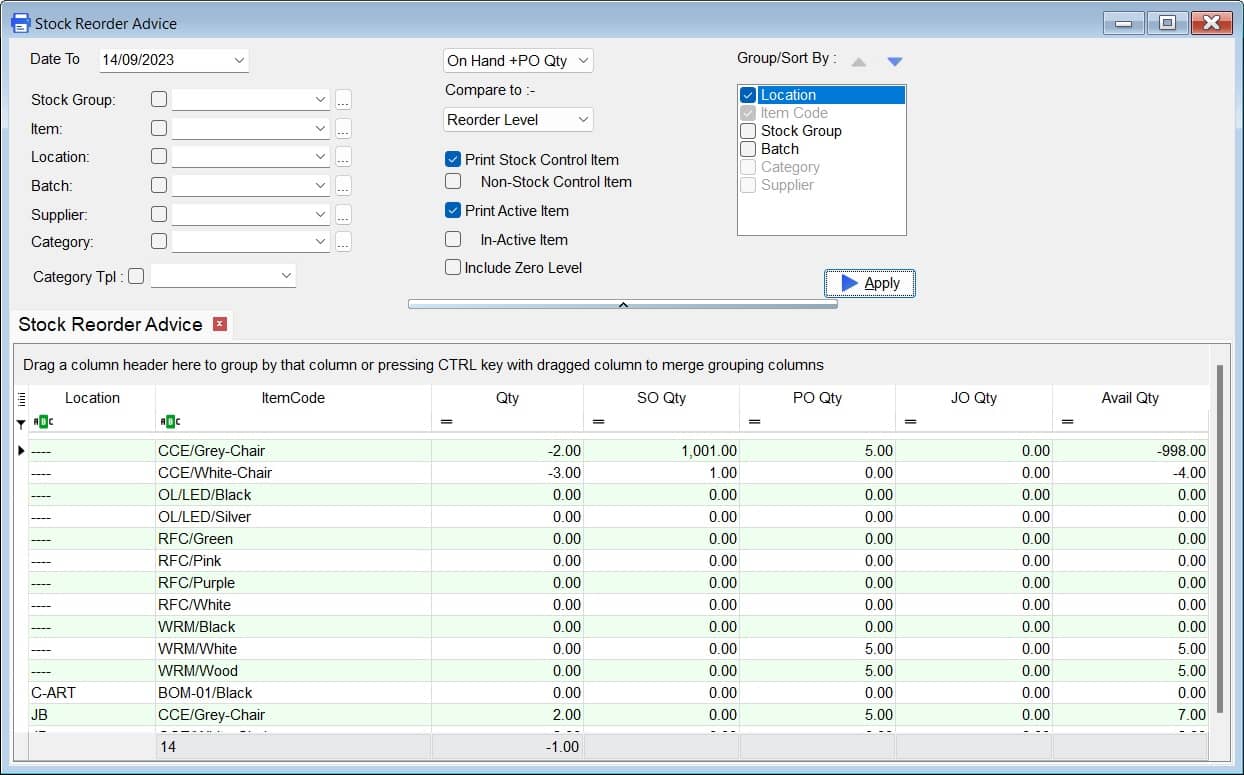

- Three Categories of Stock Reorder: A Guide to Prioritizing Your Reorders

SQL stock reorder advise report is a report that can be used to identify items that need to be reordered. The report can be divided into three categories:

- Category A: Reorder level (< 500 units): High-value items with a low frequency of sales

- Category B: Reorder level (> 500 units): Moderate value items with moderate frequency sales

- Category C: Reorder level (> 10,000 units): Low-value items with a high frequency of sales

Category A items are typically high-value items that are not sold very often. These items may be expensive to purchase or difficult to obtain. It is important to keep a close eye on the inventory levels of Category A items and to reorder them well in advance of running out.

Category B items are moderate value items that are sold at a moderate frequency. These items are typically less expensive to purchase and easier to obtain than Category A items. However, it is still important to track the inventory levels of Category B items and to reorder them in a timely manner to avoid stockouts.

Category C items are low-value items that are sold at a high frequency. These items are typically inexpensive and easy to obtain. However, due to their high sales volume, it is important to ensure that there is always enough stock of Category C items on hand.

The stock reorder advise report can be used to identify items in all three categories that need to be reordered. The report can also be used to prioritize the reordering of items based on their value and sales frequency.

Here are some tips for using the stock reorder advise report:

- Review the report regularly to identify items that need to be reordered.

- Prioritize the reordering of items based on their value and sales frequency.

- Consider the lead time for obtaining items when placing reorders.

- Set reorder points for each item based on its sales history and lead time.

- Monitor your inventory levels closely to avoid stockouts.

By using SQL stock reorder advise report effectively, businesses can ensure that they have the right amount of inventory on hand to meet customer demand and avoid stockouts.

SQL can efficiently link sales, purchase, and stock information from multiple branches and locations. This allows you to easily manage stock transactions across your entire business, regardless of where the inventory is located.

Effective inventory management can lead to increased profitability by reducing holding costs and avoiding stockouts. SQL can help you achieve this by providing you with real-time visibility into your inventory levels and transactions. This information can help you make informed decisions about reordering, pricing, and promotions.

If you are looking for a way to improve your stock inventory planning, SQL is a great option to consider. Sign up for a free demo today to see how SQL can help you boost your bottom line.

SQL Accounting Software Favoured Features

SQL Account is an accounting software that is suitable for all businesses, from small businesses to large organizations. It is crucial to find a business solution that suits the nature of your business. The right accounting software will broaden the horizons and expand business opportunities for you. Choose the best accounting software in Malaysia for your company. SQL Account is user friendly & can be integrated with no fuss.

Free Download Accounting Software trial to experience our accounting software.

Access Anytime, Anywhere

Batch Emails Statements

Special Industries Version

Real-Time CTOS Company Overview Reports

Advance Security Locks